What Is MES Monitoring?

MES (Manufacturing Execution System) monitoring involves the real-time tracking and supervision of manufacturing processes within a production facility. It encompasses various activities such as collecting and analyzing data from machines and equipment, monitoring production schedules, tracking material flow, overseeing quality control measures, and managing workforce activities on the shop floor.

MES monitoring systems enable manufacturers to gain insights into their production operations, identify inefficiencies, and make data-driven decisions to optimize productivity, minimize downtime, and ensure product quality. These systems provide visibility into key performance indicators (KPIs), such as production output, equipment utilization, cycle times, and defect rates, allowing for timely interventions to address issues and improve overall performance.

By leveraging MES monitoring, manufacturers can enhance operational efficiency, streamline workflows, reduce lead times, maintain regulatory compliance, and ultimately, achieve greater profitability. MES monitoring solutions often integrate with other enterprise systems, such as ERP (Enterprise Resource Planning) and SCADA (Supervisory Control and Data Acquisition), to facilitate seamless data exchange and holistic management of manufacturing processes.

Why Use Modern MES Monitoring?

Modern MES monitoring is the most effective way to improve your production efficiency, product quality, resource utilization and downtime. It helps you make better decisions about your production performance as well. The benefits of modern MES monitoring include:

- Increased Production Efficiency: With real-time data from sensors on every piece of equipment, you can identify bottlenecks in your process and make adjustments before they become problems. This will help you increase throughput while reducing waste.

- Improved Resource Utilization: Having real-time visibility into worker productivity gives managers the ability to schedule shifts more effectively so that each worker has time to complete their tasks without being rushed or overwhelmed by too much work at once (or underperforming due to boredom). This reduces costs associated with overtime pay for hardworking employees who are working long hours but not getting anything done because they're busy waiting on other people's processes instead.

- Reduced Downtime: Modern machine monitoring systems provide alerts when something goes wrong with one piece within an assembly line so maintenance teams can respond quickly before parts start breaking down completely--saving both time spent fixing broken machines as well as lost revenue due wasted materials/products during repairs.

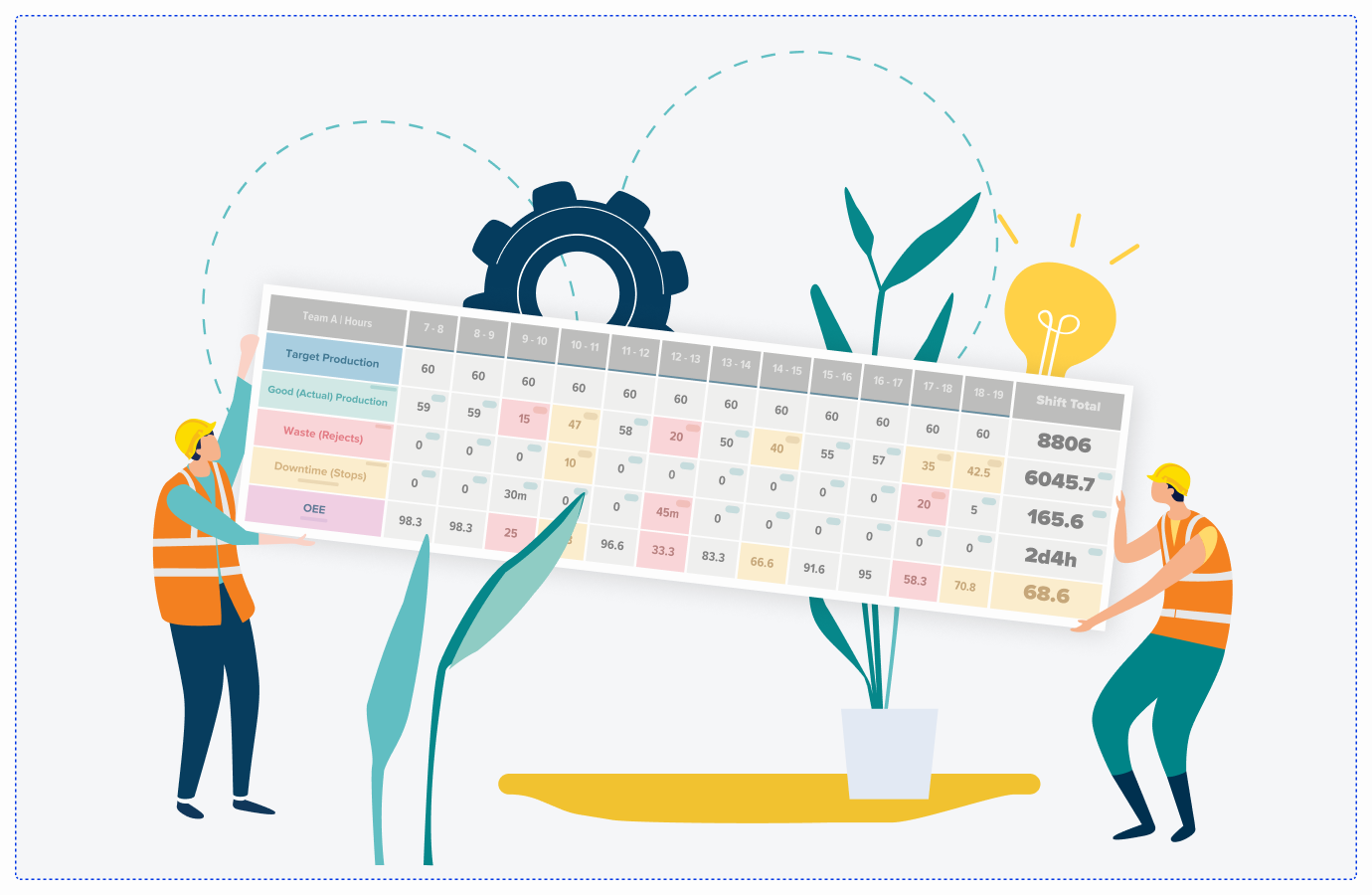

Production monitoring with production board

Challenges in manufacturing and solutions with MES

Manufacturing Execution Systems (MES) play a crucial role in addressing various challenges faced by manufacturers. Here are some common challenges and how MES solutions can provide solutions:

Production Optimization: Manufacturers often struggle to optimize production processes to meet demand while minimizing costs and waste. MES solutions offer real-time monitoring and analysis of production data, enabling proactive decision-making to optimize production schedules, resource allocation, and workflow efficiency.

Quality Management: Ensuring product quality and compliance with regulatory standards is a constant challenge for manufacturers. MES provides comprehensive quality management functionalities, including real-time quality monitoring, automated inspections, and traceability of materials and components throughout the production process, helping to identify and address quality issues promptly.

Inventory Management: Inaccurate inventory management can lead to stockouts, overstocking, and increased carrying costs. MES solutions offer inventory tracking and management capabilities, providing visibility into inventory levels, material usage, and replenishment needs in real time, thereby optimizing inventory levels and reducing holding costs.

Equipment Downtime: Unplanned equipment downtime can disrupt production schedules and lead to lost revenue. MES systems enable predictive maintenance by monitoring equipment health in real time, analyzing historical data to identify potential issues, and scheduling maintenance activities proactively to prevent costly breakdowns.

Regulatory Compliance: Meeting regulatory requirements and maintaining compliance with industry standards is essential for manufacturing operations. MES solutions streamline compliance management by providing audit trails, electronic documentation, and automated reporting capabilities, ensuring adherence to regulatory guidelines and facilitating the certification process.

Supply Chain Visibility: Lack of visibility into the supply chain can result in delays, disruptions, and inefficiencies. MES solutions offer supply chain visibility by integrating with suppliers, distributors, and logistics partners, providing real-time insights into inventory levels, production status, and delivery schedules, enabling better coordination and collaboration across the supply chain.

Data Management: Managing vast amounts of data generated by manufacturing operations can be overwhelming. MES solutions centralize data management, offering a single source of truth for all manufacturing-related data, with features such as data collection, storage, analysis, and visualization, empowering manufacturers to derive actionable insights and drive continuous improvement initiatives.

Modern MES monitoring for operations managers

Modern MES monitoring provides real-time insights into production processes, enabling operations managers to make data-driven decisions and improve production performance. By leveraging advanced analytics, machine learning, and real-time data, modern MES helps managers monitor production efficiency, detect production issues early, and minimize downtime.

Shift complete success

Conclusion

Modern MES monitoring provides real-time insights into production processes, enabling operations managers to make data-driven decisions and improve production performance. By leveraging advanced analytics, machine learning, and real-time data, modern MES helps managers monitor production efficiency, detect production issues early, and minimize downtime.