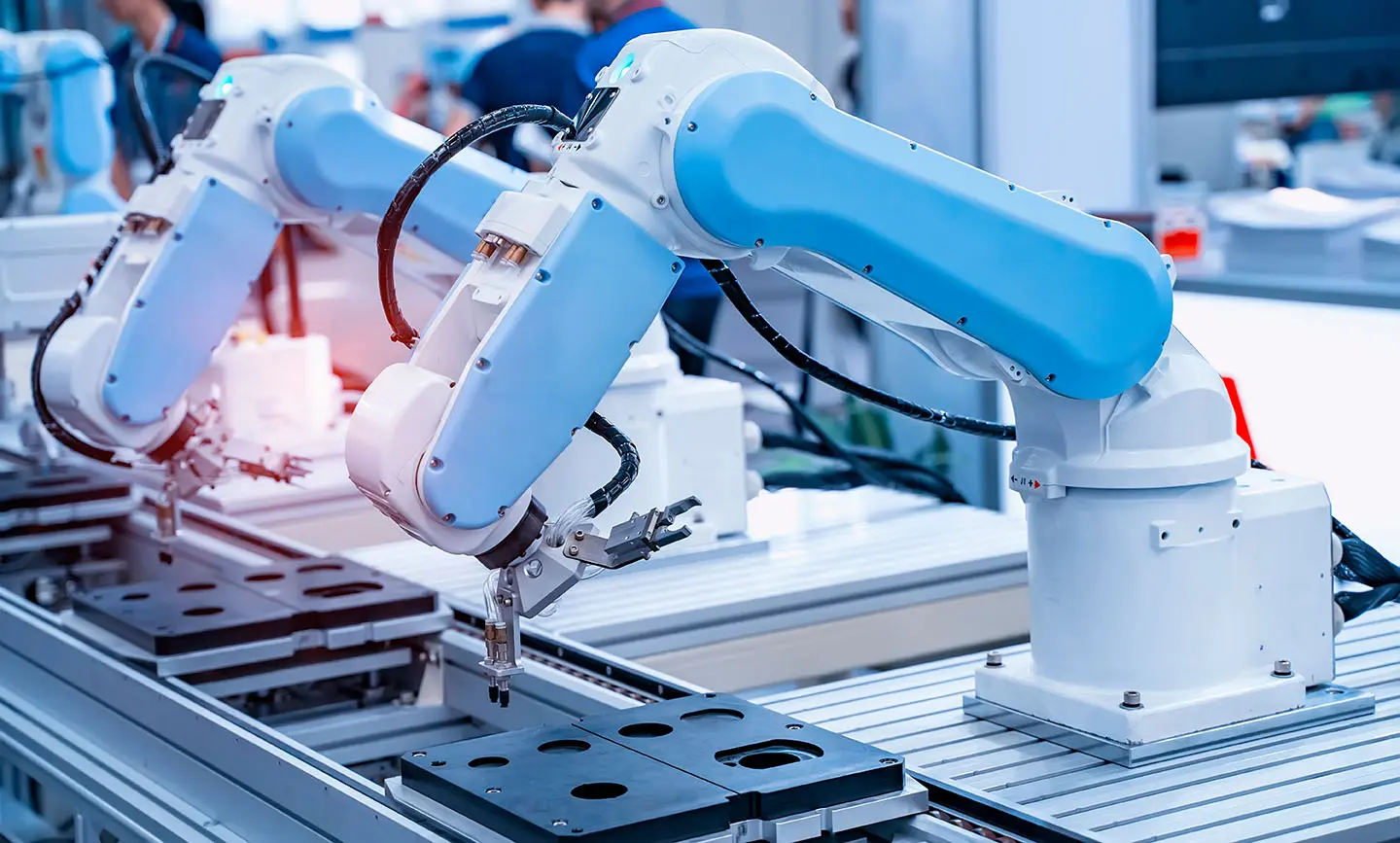

Precision Parts Manufacturing faces several challenges, including manual processes, paperwork, and siloed data that lead to inefficiencies, errors, and compliance issues. These issues can make it difficult for manufacturers to meet quality standards, maintain precision, and remain competitive in a demanding market.

Precision Parts Manufacturing faces several challenges, including manual processes, paperwork, and siloed data that lead to inefficiencies, errors, and compliance issues. These issues can make it difficult for manufacturers to meet quality standards, maintain precision, and remain competitive in a demanding market. IfElseCloud MES streamlines Precision Parts Manufacturing processes and enables manufacturers to improve precision, efficiency, and quality control. Automating processes like report creation and data entry, identifying bottlenecks in real-time, and leveraging AI and machine learning optimizes processes and improves product quality. By adopting IfElseCloud MES, manufacturers can improve operations, reduce costs, and attract a younger workforce by embracing digital transformation and Industry 4.0 concepts. IfElseCloud MES is a vital tool in advancing Precision Parts Manufacturing, positioning the industry for success in a demanding and competitive market.

Revolutionize operations with the power of smart modern MES apps, eliminating the hassle of manual paperwork and whiteboards, and unlocking a new era of productivity, accuracy, and agility. Adopt digital transformation.

Adopt forward-thinking digital strategies and MES technologies that propel businesses into the future, enabling achieve goals.

Harness the power of cloud and digital industrial technology to transform processes and achieve higher efficiency.

Take a critical look at the production processes, implementing strategic improvements to smooth workflows.

Base decisions on data insights, enabling you to make informed choices that lead to higher efficiency in the manufacturing.

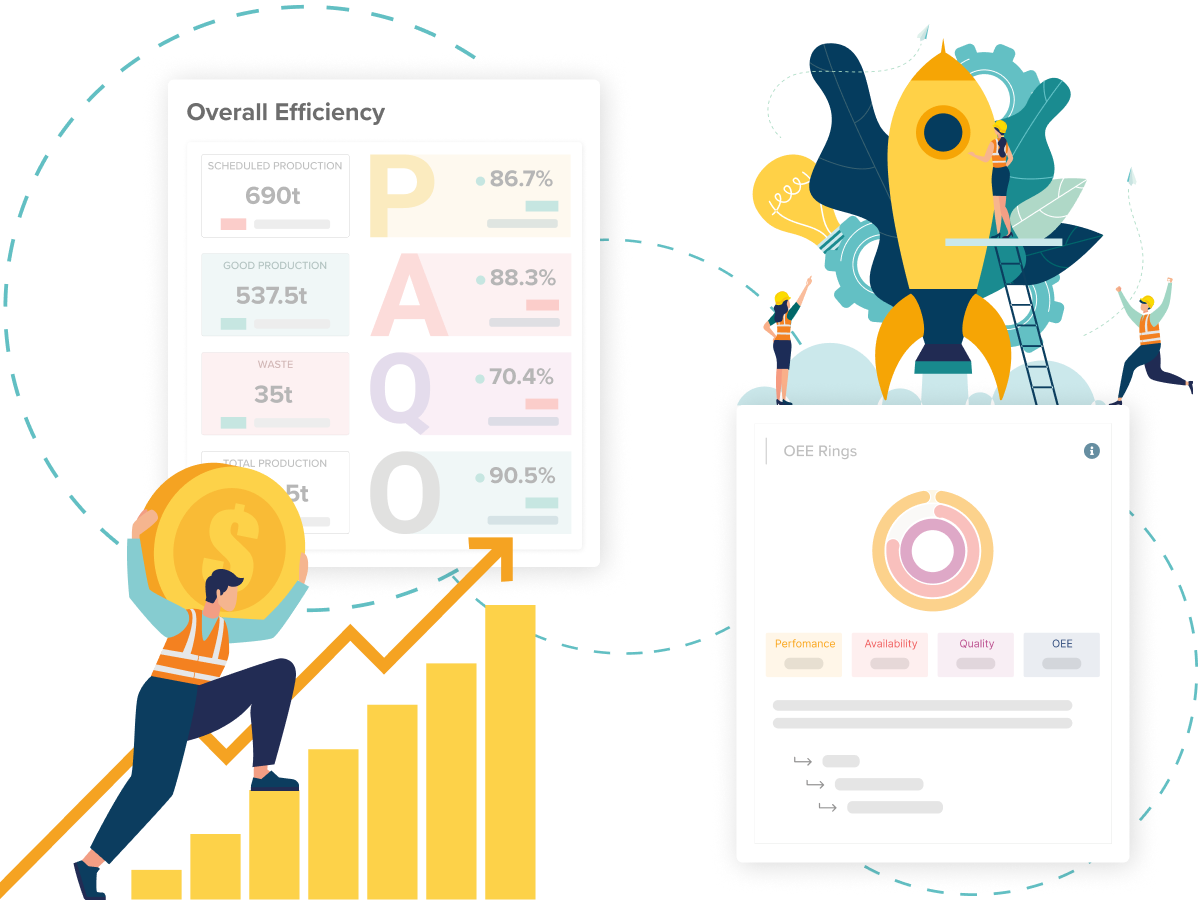

Experience a remarkable boost in efficiency through a comprehensive approach that targets performance, availability, and quality. Drive continuous improvement, exceed customer expectations in the precision parts manufacturing industry.

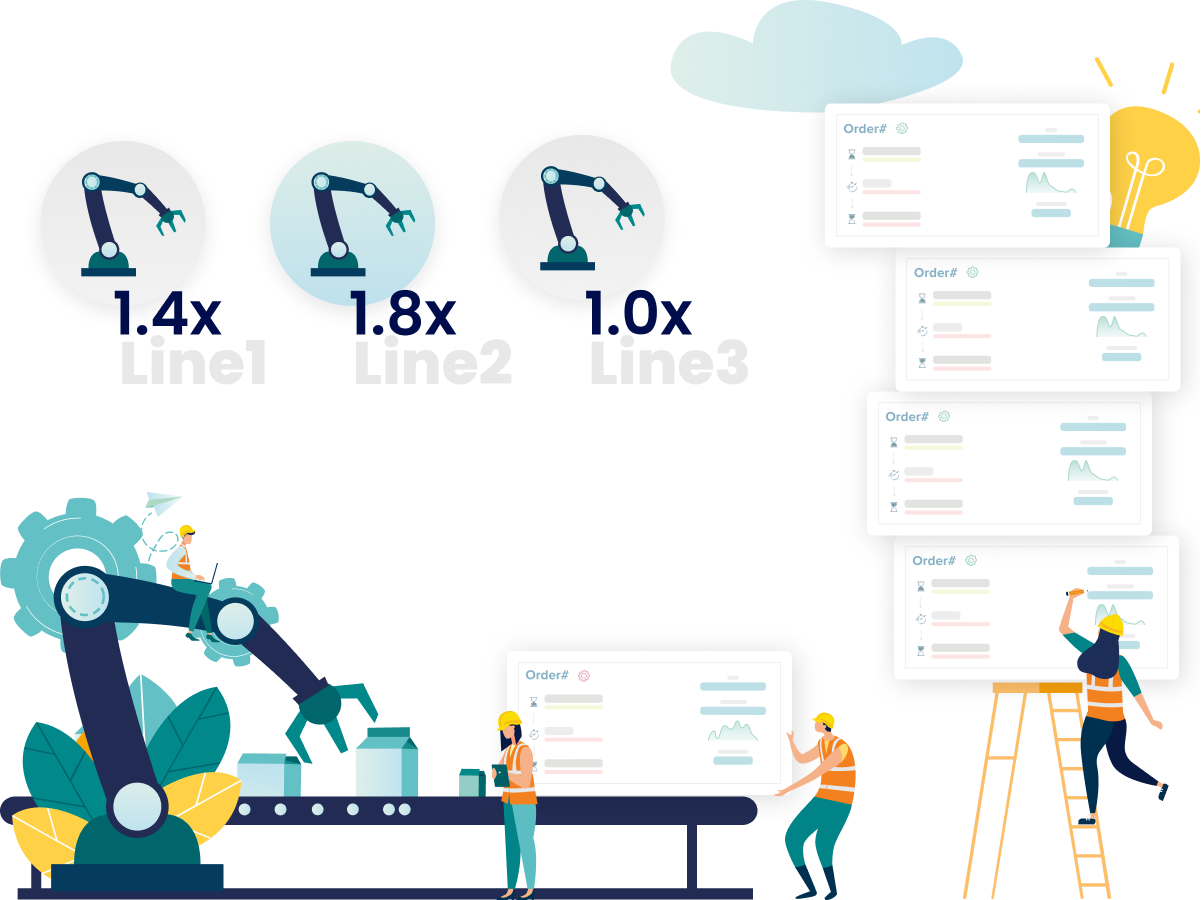

Providing real-time insights with our MES, enabling prompt interventions, and driving continuous line efficiency and performance improvement.

Instant access to critical performance metrics, enabling timely interventions with MES production dashboards.

Visualize workloads, balance tasks, and optimize resource allocation for maximum productivity with MES pacing boards.

Track and analyze the root causes of production failures and make data-driven decisions.

Capture the attention of the younger workforce with cutting-edge technology solutions by adopting modern MES. Ditch the paperwork and empower your team with efficient digital manufacturing tools.

Embrace a digital MES revolution and bid farewell to paper-based processes. Go paperless to attract and retain the tech-savvy talent of today.

Tech-driven digital manufacturing workplace designed for the younger workforce. Boost productivity with next-gen MES tools.

Stay ahead in manufacturing with a proactive outlook. Embrace innovation, automation, and digital transformation with our modern MES platform.

Embrace mobile MES technology to meet the expectations of younger workers. Enable on-the-go access.

Leverage a private assistant for asset management. Gain valuable insights on MTBF, MTTR, and MTTF, optimizing maintenance strategies for optimal performance with digital manufacturing.

Maximize operational efficiency and reduce downtime by leveraging powerful MES asset management metrics for informed decision-making.

Calculate Mean Time Between Failures (MTBF) for improved maintenance scheduling and optimized asset reliability.

Minimize equipment downtime with our MES and MTTR metrics, enabling swift repairs and maximizing operational uptime.

Predict equipment failures with MTTF data, enabling proactive maintenance and minimizing operational disruptions.

Simplify work order management through a built-in smart scheduler that harnesses the power of machine learning and AI, enabling seamless task allocation with our MES platform.

Achieve optimal work order scheduling outcomes by leveraging digital transformation and data-driven approaches, enabling better resource allocation.

Achieve smooth work order management with our flexible digital MES visualization options, optimizing resource utilization.

Optimize work order scheduling effortlessly, improving operational efficiency with automated task allocation in our MES.

Effortlessly synchronize work order management with our MES platform, ERP and e-commerce, ensuring seamless data flow.

With the help of our latest MES platform, empower your maintenance team with a robust planning and scheduling solution, making it easy to coordinate tasks and ensure smooth operations for maximum efficiency.

With our MES, achieve visual clarity in maintenance planning, enhancing task coordination and enabling seamless workflow for improved efficiency.

Optimize task coordination and workflow management with MES visualization for work orders Gantt & Calendar views.

Effortlessly manage repetitive maintenance tasks with recurring scheduling with our digital platform.

Optimize breakdown maintenance with standardized operating procedures with our MES.

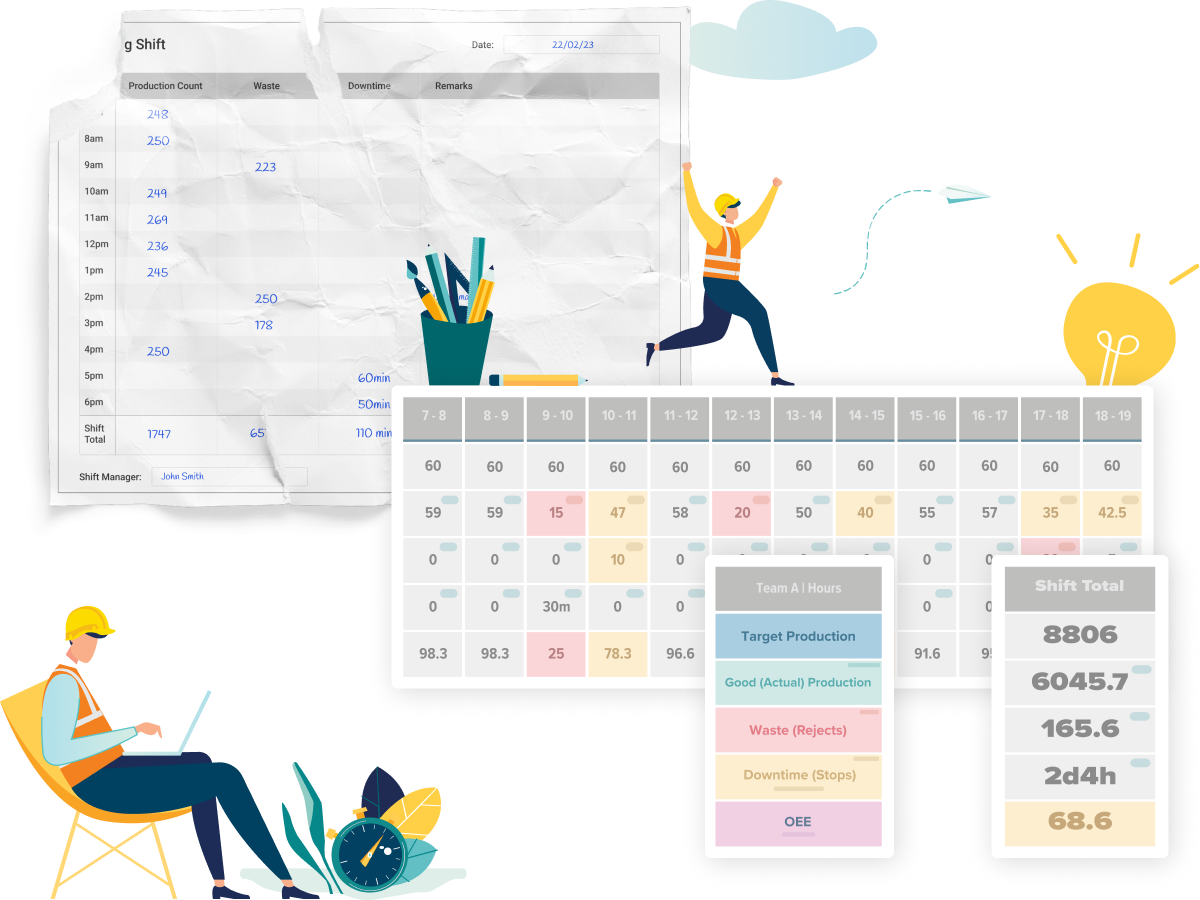

Our digital manufacturing MES platform, seamlessly generated automated and real-time reports, empowering you with up-to-date information, eliminating delays, and enabling prompt response to changing precision parts manufacturing needs.

Our digital workflow with automated and real-time reports, eliminating the need for papers and whiteboards with our MES platform.

Empower manufacturing teams with automated reporting, enabling data-driven decisions and operations with our MES.

Drive successful organizational change with paperless solutions designed for business transformation leaders.

Drive financial agility with customizable reporting solutions, empowering executives to adapt to dynamic market conditions.

Empower teams with a centralized data platform, promoting collaboration, knowledge sharing, and data-driven insights for effective teamwork with the help of our advanced MES platform.

Break free from data silos and unlock the full potential of your organization's collective knowledge and insights with the MES.

Foster digital collaboration among teams, promoting agile decision-making and efficient project execution.

Break down data barriers and foster inclusivity with a solution that ensures information is available to all team members.

Drive iterative enhancements through a continuous feedback loop, enabling timely adjustments and optimal outcomes.

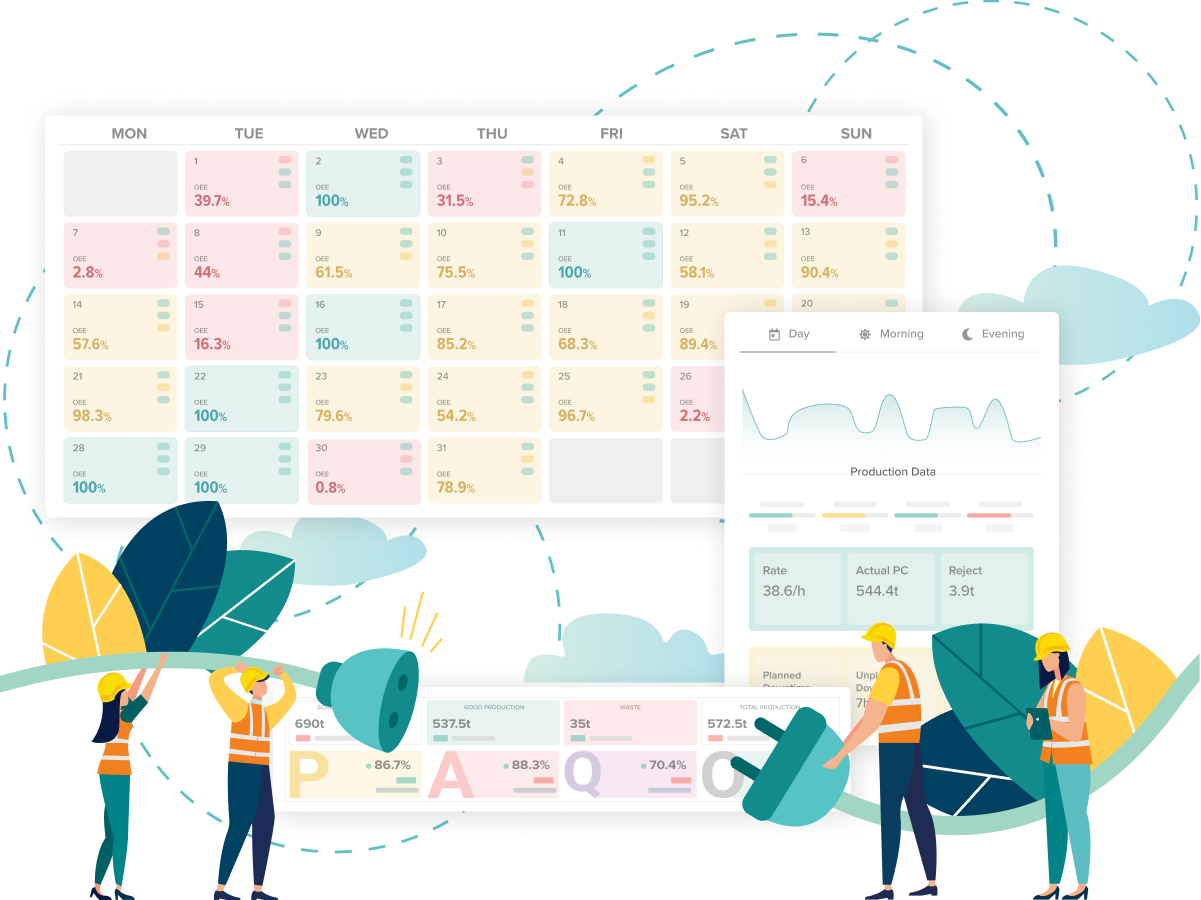

Leverage the richness of your manufacturing data to uncover valuable patterns, trends, and correlations that drive better decision-making with the modern manufacturing execution system.

Optimize operations with data-driven manufacturing decisions, leveraging analytics for continuous improvement with our digital MES.

Uncover root causes behind manufacturing inefficiencies with digital MES, enabling targeted improvements and cost savings.

Gain visibility into production trends for data-driven decision-making, driving operational efficiency with the MES.

Minimize financial losses by optimizing costs across the manufacturing process and maximizing resource efficiency.

Take full control with a white-label MES platform that allows you to customize it to your branding, locale, and manufacturing processes with our digital manufacturing tool.

Adapt the MES platform to your manufacturing processes, enabling seamless integration and improved decision-making capabilities.

Monitor production and metrics for real-time visibility and performance management with our MES.

Personalize the MES platform with branded interfaces and localized language support.

Capture the nuances of your product range and facilitate efficient production planning.

120+

On-the-go access to real-time acquisition and entry data, enabling remote monitoring and quick decision-making, helps solve the lack of real-time data visibility challenges.

IfElseCloud’s utilizing analytics identifies and resolves inconsistencies, improving data accuracy and reliability.

IfElseCloud implements role-based access controls, allowing authorized users to access relevant data and help break down silos.

Generates reports to meet compliance requirements, enabling traceability and accountability, and solving traceability problems.

IfElseCloud leverages advanced analytics to uncover insights and opportunities for production process optimization and help solve inefficient production processes.

Collaborative demand planning, involves stakeholders to gain insights and respond quickly and effectively to demand changes.

IfElseCloud's real-time monitoring capabilities enable organizations to identify inefficiencies and help solve production process challenges.

IfElseCloud's process mapping features enable organizations to visualize and analyze production processes, identifying bottlenecks and inefficiencies.

IfElseCloud's asset management capabilities enable organizations to manage maintenance and repairs efficiently, reducing downtime and improving productivity.

Our MES tracks maintenance activities in real time, ensuring timely upkeep of equipment and preventing bottlenecks.

These capabilities enable organizations to identify the underlying causes of waste and scrap, enabling targeted process improvement.

IfElseCloud provides real-time monitoring of production costs, enabling accurate and up-to-date cost tracking and helping solve the inability to track production costs.

IfElseCloud's branding features enable organizations to create a strong brand image and enhance competitiveness through effective brand management.

Enable organizations to offer flexible work options, improving work-life balance and enhancing the attraction of skilled workforce.

With the help of IfElseCloud, organizations can provide employees with flexible work arrangements and support work-life balance, helping in solving the difficulty in retaining an experienced workforce.

IfElseCloud's process optimization capabilities enable organizations to optimize their processes, preventing bottlenecks and enhancing process efficiency.

IfElseCloud enables organizations to facilitate communication through notes among employees and departments.

With the help of our MES, enhance employee productivity and reduce manual labor costs through effective task management.

Organizations create teams consisting of employees from different departments, facilitating collaboration, and tracking production costs.

IfElseCloud's data visualization capabilities enable organizations to visualize data and make informed decisions quickly, helping solve slow decision-making challenges.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the precision parts industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your automobile precision parts operations.